Products

Contact Us

Sales Hotline:

Manager Li: 86-186-5312-9070

E-Mail: zgjngx@163.com

Address: Biandiandong Road, Huaiyin District, Jinan City,Shandong Province

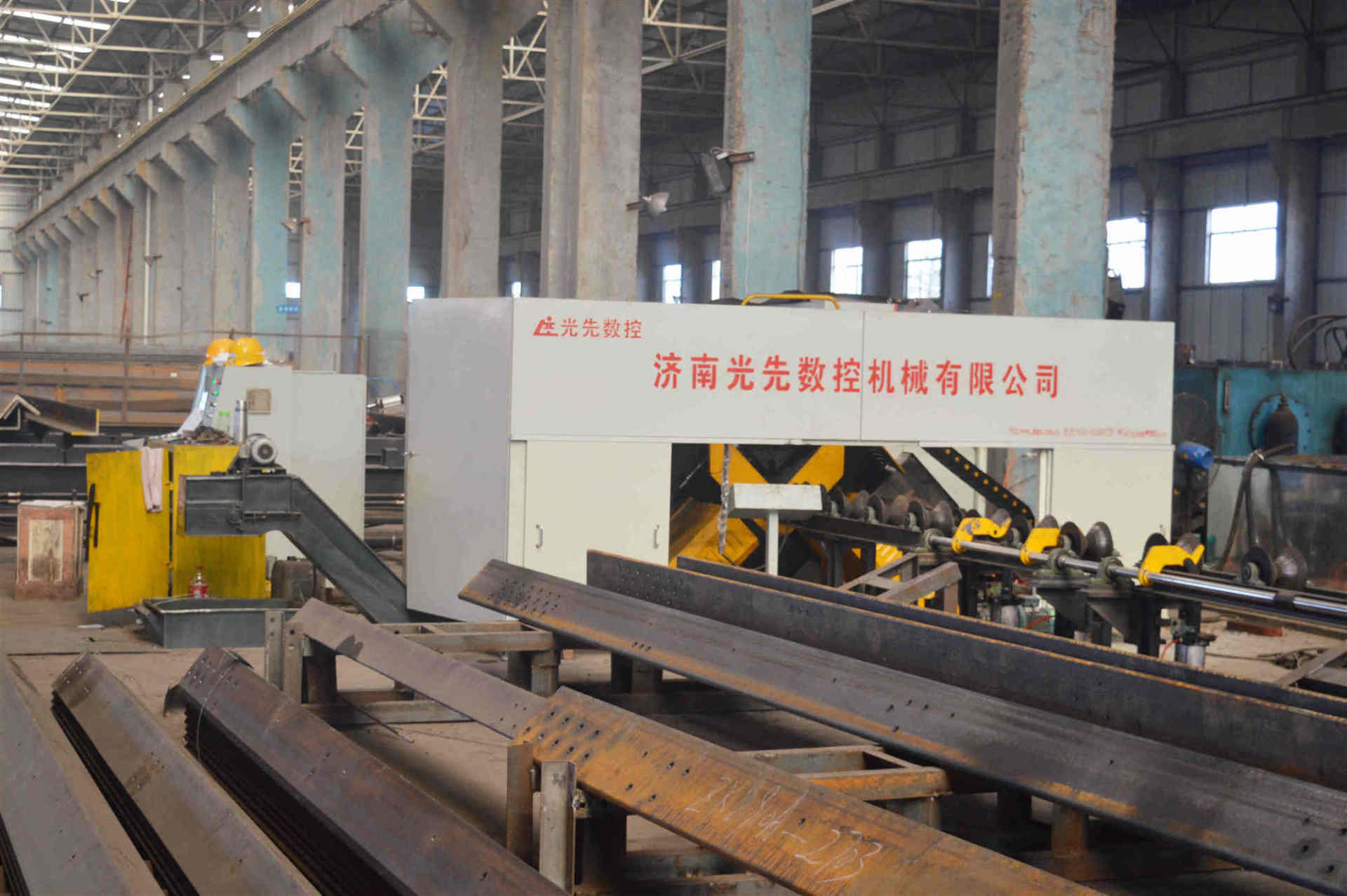

JNC3640G high-speed CNC angle steel punching, drilling (sawing or shearing) production line

Details

This product has won two national patents, with patent numbers: ZL 2009 2 0017589.0; ZL 2009 2 17585.2

Product Features

Nominal marking force 1200kN, can achieve 18 marking characters, optional 4 sets of marking character heads, marking distance can be arbitrarily set.

The drilling unit is equipped with two sets of CNC drilling power heads, each set is equipped with three collets, each collet is equipped with one type of drill bit, a total of three sets of drill bits with different diameters are installed, which can realize automatic and rapid replacement of drill bits, and all holes on the angle steel can be processed at one time. The drilling spindle adopts Taiwan precision spindle (internal cooling); high-speed drilling with cemented carbide internal cooling drill bits.

Optional sawing unit, CNC control of the whole process of angle steel marking, drilling and sawing. Realize automation, high precision, multi-variety and mass production.

The CNC feed carriage is driven by a servo motor, with feedback from a photoelectric encoder, closed-loop control, and high positioning accuracy.

The host computer adopts a Chinese interface, which is simple to operate and can accept workpiece processing programs generated by layout software, or manual programming.

| Machine Model |

JNC3640G |

| Machine Function |

Drilling, marking, sawing |

| Processing angle steel size range (mm) |

L125×125×10~L360×360×40 |

| Max. drilling diameter (mm) |

40 |

| Drilling spindle speed (r/min) |

6000 |

| Drilling spindle taper hole |

BT40 |

| Spindle stroke (mm) |

140 |

| Moving speed of power head (m/min) |

10 |

|

Adjustment range of standard distance (mm) |

50~220 |

| Number of spindle per side |

1 |

| Marking Force (kN) |

1200 |

| Number of marking groups (groups) |

1 (4 optional) |

| character head number of each group |

18 |

| character head size (mm) |

14×10×19 |

| Size range of shear angle steel (mm) |

L125×125×10~L200×200×20 (optional) |

|

Saw angle steel size range (mm) |

L125×125×10~L300×300×40 (optional) |

| Max. length of blank angle steel (m) |

|

| Max. length of finished angle steel (m) |

14 |

| The machining accuracy |

Meets the requirements of GB2694 |

| Hydraulic system |

Water cooling (optional for air cooling and automatic heating) |

| Number of NC axes |

7 |

| Overall dimension (mm) |

32600×7500×2500 |

Get a free quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!