Products

Contact Us

Sales Hotline:

Manager Li: 86-186-5312-9070

E-Mail: zgjngx@163.com

Address: Biandiandong Road, Huaiyin District, Jinan City,Shandong Province

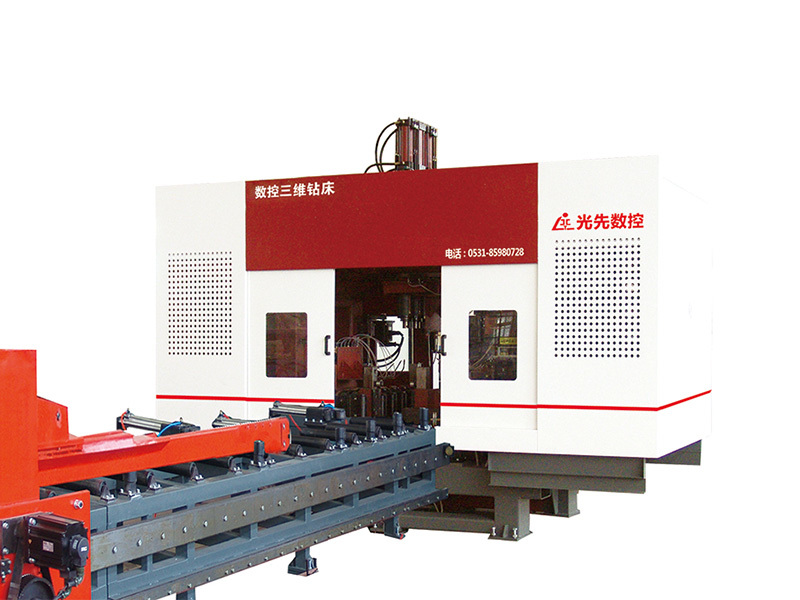

SWZ500 CNC H-beam three-dimensional drilling machine

Details

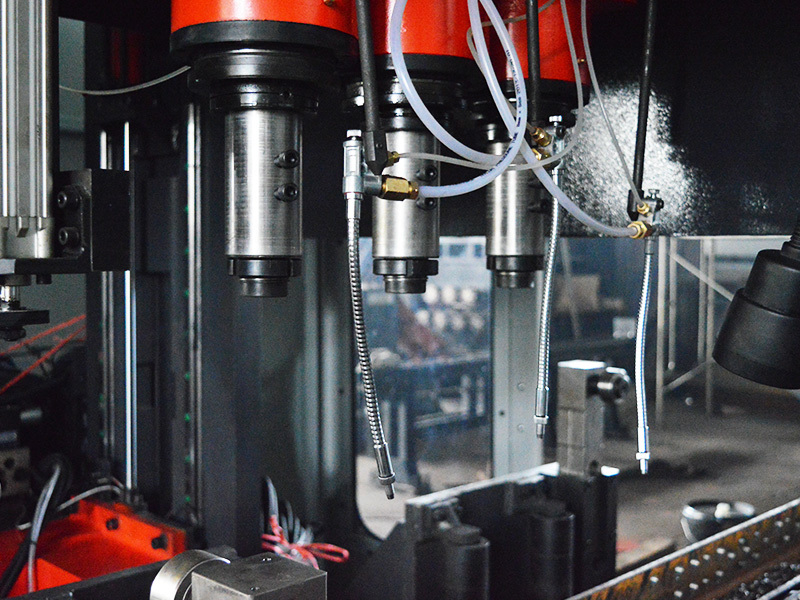

A CNC three-dimensional drilling machine mainly consists of several parts: the main unit, three-dimensional drill feeding mechanism, three-dimensional drill discharging chute, cooling system, hydraulic system, pneumatic system, lubrication system, electrical system, and waste material cart. The machine adopts a fixed bed and moving workpiece structure, suitable for processing medium and small steel parts and facilitating automated production.

The machine's control system consists of a host computer and PLC. Programming methods include keyboard input, USB input, and CAD-generated processing programs. Processing programs can be stored, called, displayed, and communicated at any time according to the part number. The machine can achieve both individual manual adjustment control of various processing parameters and fully automatic control processing.

To ensure the reliability and durability of the machine, the linear rolling guide rails, servo motors, servo amplifiers, frequency converters, and hydraulic components used in this machine are all products of world-renowned brands.

Main Technical Parameters:

| Parameter Name |

Unit |

Parameter Value |

Remarks |

||

| Workpiece |

Width Range |

mm |

100~500 |

|

|

| Height Range |

mm |

100~500 |

|

||

| Minimum Automatic Feeding Length |

mm |

2000 |

|

||

| Maximum Workpiece Length |

mm |

12000 |

|

||

| Spindle |

Number of Spindles |

pcs |

9 |

|

|

| Spindle Motor Power |

Kw |

Approximately 5.5 |

|

||

| Speed Range of Each Spindle |

r/min |

180~560 |

|

||

| Drilling Diameter Range |

mm |

φ12~φ30 |

|

||

| Number |

X-axis |

Servo Motor Power |

Kw |

Approximately 4.5 |

|

| Maximum Speed |

m/min |

40 |

|

||

| Y-axis |

Servo Motor Power |

Kw |

Approximately 1.5 |

|

|

| Maximum Speed |

m/min |

10 |

|

||

| Z, W-axis |

Servo Motor Power |

Kw |

Approximately 1.5 |

|

|

| Maximum Speed |

m/min |

10 |

|

||

Get a free quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!