Products

Contact Us

Sales Hotline:

Manager Li: 86-186-5312-9070

E-Mail: zgjngx@163.com

Address: Biandiandong Road, Huaiyin District, Jinan City,Shandong Province

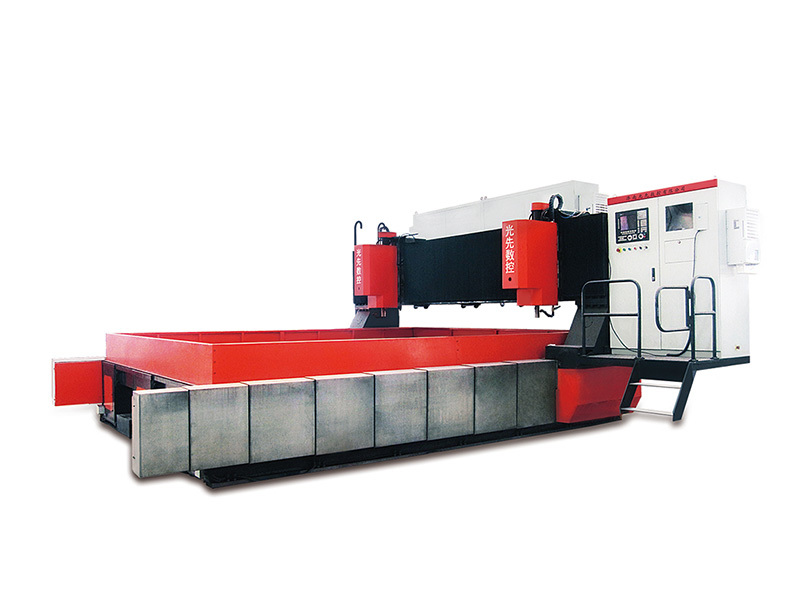

PZ4040 Gantry-type CNC Planer Drilling Machine

Details

This equipment can drill holes in both single and composite materials, and in addition to through holes, it can also process blind holes and stepped holes. Ordinary twist drills are used.

This equipment mainly consists of a bed worktable, a mobile gantry, a drilling power head, an automatic chip remover and a circulating cooling device, and an electrical system. This equipment is mainly aimed at drilling and processing flat plates such as building steel structures, power transmission towers, and petrochemical equipment. The equipment adopts a gantry moving structure, longitudinal movement (X-axis), transverse movement (Y-axis), and vertical movement of the drilling power head (Z-axis), all driven by servo motors through precision ball screw guide rails. It can automatically, accurately, and quickly locate and automatically complete the drilling process. It greatly improves the drilling accuracy and speed. At the same time, it avoids the possibility of rework or scrap of workpieces caused by manual positioning and drilling errors.

Equipment Parameters

1、Machine Type Gantry-type CNC drilling machine

2、Maximum workpiece clamping size 4000×4000mm

3、Maximum workpiece processing thickness 200mm

4、Drilling power head type Single-spindle slide-type servo-controlled power head

5、Number of drilling power heads 2

6、Main spindle Morse taper Morse taper No. 5

7、Drill bit loading and unloading method Quick-change tool

8、Maximum drilling diameter Φ60mm

9、Main spindle motor power 2×7.5KW

10、Main spindle speed 100~500r/min

11、Vertical travel of power head slide (Z-axis) 350mm

12、Z-axis servo motor power 2×1.5KW

13、Gantry longitudinal (X) travel 4000mm

14、X-axis servo motor power 2×3KW

15、Power head transverse (Y-axis) travel 4000mm

16、Y-axis servo motor power 2×1.5KW

17、Number of CNC axes 6

18、Machine Accuracy

Positioning accuracy ≤±0.25mm

Repeatability ≤±0.12mm

Get a free quote

Please fill in your contact information and your needs, and we will arrange a professional to contact you!