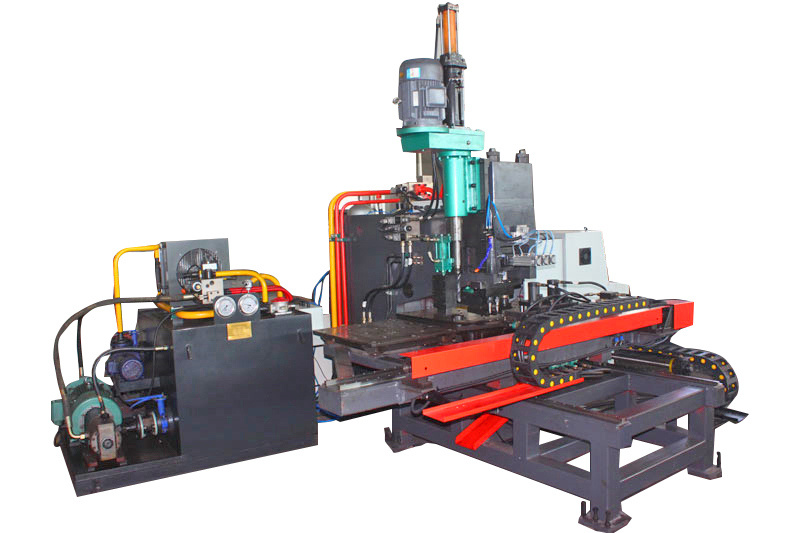

Jinan Guangxian NC100 type connection plate punching machine CNC plate punching machine

Release time:

2022-05-18

The BNC100 CNC connecting plate punching machine is a PLC-controlled hydraulic CNC punching and marking machine developed by our company for steel structure processing manufacturers. It can automatically punch and mark various types of flat metal plates.

The BNC100 CNC connection plate punching machine is a PLC-controlled hydraulic CNC punching and marking machine developed by our company for steel structure processing manufacturers. It can automatically punch and mark various types of flat metal plates.

The main features of the BNC100 CNC connection plate punching machine are as follows:

1. The machine adopts a safer and more reliable C-type welded structure, which can ensure stable operation during punching. The punching oil cylinder and the main unit are designed as separate units, making daily maintenance and upkeep easier.

2. The BNC100 CNC punching machine is a multi-station punching machine. The mold is changed during the punching process through a mold changing cylinder, allowing for one-time processing of the workpiece and the ability to process 2-3 different hole diameters.

3. The die position of the BNC100 CNC connection plate punching and marking machine is designed and installed on the operator's side, making it easier and faster to change the character box.

4. The CNC connection plate punching machine uses a commercial industrial control computer for program compilation and process monitoring. It is easy to operate and requires a relatively low entry threshold for operators.

5. The BNC100 CNC punching machine can meet the needs of long-term continuous production. It is stable in production and processing, has a low failure rate, and is reasonably priced, making it an ideal automated punching machine for related industries.

Latest news

Jinan Evershining CNCMachine Co., Ltd.'s roll forming production line is a CNC-controlled metal sheet processing equipment. It can be customized to meet the processing requirements of various industries, considering factors such as product dimensions, shapes, raw material types, and specifications.

The Guangxian CNC JNC1412 CNC angle steel production line is a PLC-controlled automated angle steel punching and shearing production line that can automatically complete steel stamping, punching on both sides, fixed-length cutting, and corner cutting of rough angle steel blanks. It also has auxiliary functions such as automatic feeding and automatic unloading. The entire production line can be operated by a single person, integrating multiple processing procedures into a single production line to achieve automated processing of angle steel workpieces.

Jinan Evershining CNCMachine Co., Ltd.'s photovoltaic bracket cold bending production line is a fully automatic forming and processing equipment. The production line can uncoil and flatten galvanized rolls of various thicknesses and widths, then process them through a CNC punching unit and a roll forming unit, and finally cut them to size to produce finished photovoltaic brackets. The production line uses PLC control, and the entire production process is automated. Operators issue commands and monitor the machine tools through the upper computer mouse and keyboard operations.

The Guangxian CNC JNC2020 CNC angle steel line is a fully automatic angle steel punching and shearing production line equipment, PLC CNC control, automated operation, currently mainly used in the automated processing of angle steel components in the power transmission towers, communication towers, and building steel structure industries, and is an indispensable automated production equipment in the above industries.

Jinan Evershining CNCMachine Co., Ltd.'s JCBNC14 CNC steel punching, shearing and cutting production line is used for the automated punching and shearing processing of angle steel, flat steel, and channel steel. It can be used in the electric power fittings and building steel structure industries and can serve as auxiliary processing equipment in addition to CNC angle steel production lines and CNC channel steel production lines, meeting the various processing needs of manufacturers.

In addition to solar energy combiner forming machines, our company's roll forming production line and cold bending forming equipment can also be applied to various industries such as power, pipe galleries, curtain walls, high-speed rail, expressways, and light steel construction. We can provide automated solutions based on your processing requirements. Welcome to communicate and exchange with us! Manufacturer selection contact information: Zhu Gong 18668977659