Sales Support

Contact Us

Sales Hotline:

Manager Li: 86-186-5312-9070

E-Mail: zgjngx@163.com

Address: Biandiandong Road, Huaiyin District, Jinan City,Shandong Province

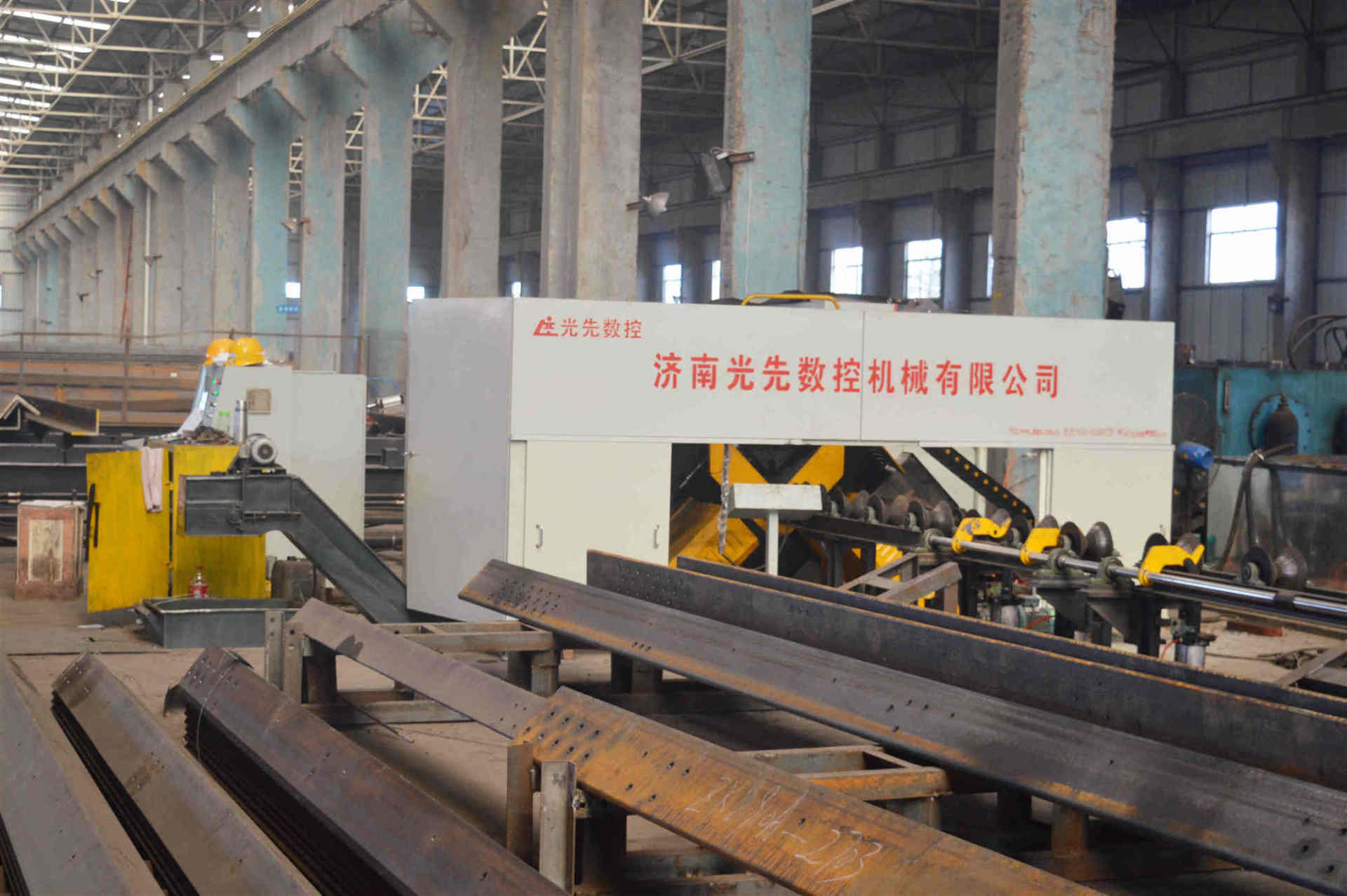

High-speed CNC angle steel drilling production line for large-specification angle steel of power transmission towers--Jinan Guangxian JNC3040G3 model, manufacturer direct sales

The JNC3040G3 high-speed CNC angle steel drilling production line is a fully automatic CNC production line developed by our company's technology R&D department for manufacturers of ultra-high voltage and extra-high voltage power transmission towers. It is used for high-speed drilling of large-specification, high-strength angle steel. This production line is suitable for high-speed drilling of angle steel ranging from ∟125×125×10mm to ∟300×300×40mm. The maximum drilling diameter can reach 40mm, and the maximum thickness of the processed angle steel can also reach 40mm. The production line uses a high-speed drilling spindle, and the maximum speed during processing can reach 6000r/min, resulting in extremely high processing efficiency.

The JNC3040G3 high-speed CNC angle steel drilling production line was developed by our company's technology research and development department for manufacturers of ultra-high voltage and extra-high voltage power transmission towers. It is a fully automatic CNC production line used for high-speed drilling of large-specification, high-strength angle steel.

This production line is suitable for ∟125×125×10mm~∟ 30 0× 30 0× Angle steel within the specification range of 40mm can be processed with high-speed drilling. The maximum drilling diameter can reach 40mm, and the maximum thickness of the processed angle steel can also reach 40mm. The production line uses a high-speed drilling spindle, and the maximum speed during processing can reach 6000r/min, with extremely high processing efficiency.

The performance advantages of our company's JNC3040G3 high-speed CNC angle steel drilling production line are as follows:

1. The production line adopts a host computer + PLC control method, the programming operation is simple and easy to learn, the production line has a high degree of automation, and can automatically complete marking and drilling.

2. The production line uses a servo motor to drive the feeding trolley to locate the workpiece processing position, and is assisted by a photoelectric induction switch for positioning, closed-loop control, high processing positioning accuracy, and can effectively ensure the processing accuracy of the production line.